Glyoxylic acid is an important pharmaceutical intermediate and organic synthesis intermediate. It can synthesize a variety of compounds, so it has a wide range of applications in medicine, fragrance, paint, papermaking, fine chemicals and other fields.

At present, the most commonly used methods for producing glyoxylic acid in industry are oxalic acid electrolysis reduction method, glyoxal nitric acid oxidation method and ozone oxidation method. With the continuous strengthening of domestic environmental protection policies and requirements, the traditional production processes such as glyoxal nitric acid oxidation method will face huge environmental protection pressure, and some domestic enterprises have stopped production. Moreover, the traditional glyoxal nitric acid oxidation method is difficult to improve the quality of glyoxylic acid products due to production process constraints, and it is an inevitable trend to be eliminated due to environmental protection pressures.

However, Guolin New Materials has solved the world's most advanced technical problems in the production of glyoxylic acid by ozone oxidation maleic anhydride method, fundamentally improved the utilization rate of ozone, thereby greatly reducing production costs, improving product quality, and improving product competitiveness., occupied the high-end glyoxylic acid app store in one fell swoop, and formed the proprietary technology of ozone oxidation maleic anhydride crystal glyoxylic acid. This production process can produce high-quality crystalline glyoxylic acid, which lays the foundation for the development of my country's fine chemical industry and energy conservation and emission reduction.

Through comprehensive comparison, it is found that the current Guolin new material ozone oxidation maleic anhydride method can be industrialized to prepare high-quality crystalline glyoxylic acid products. The reaction conditions are mild, the product quality is good, it is a non-dangerous transportation product, and the pollution is less. The by-product potassium formate.

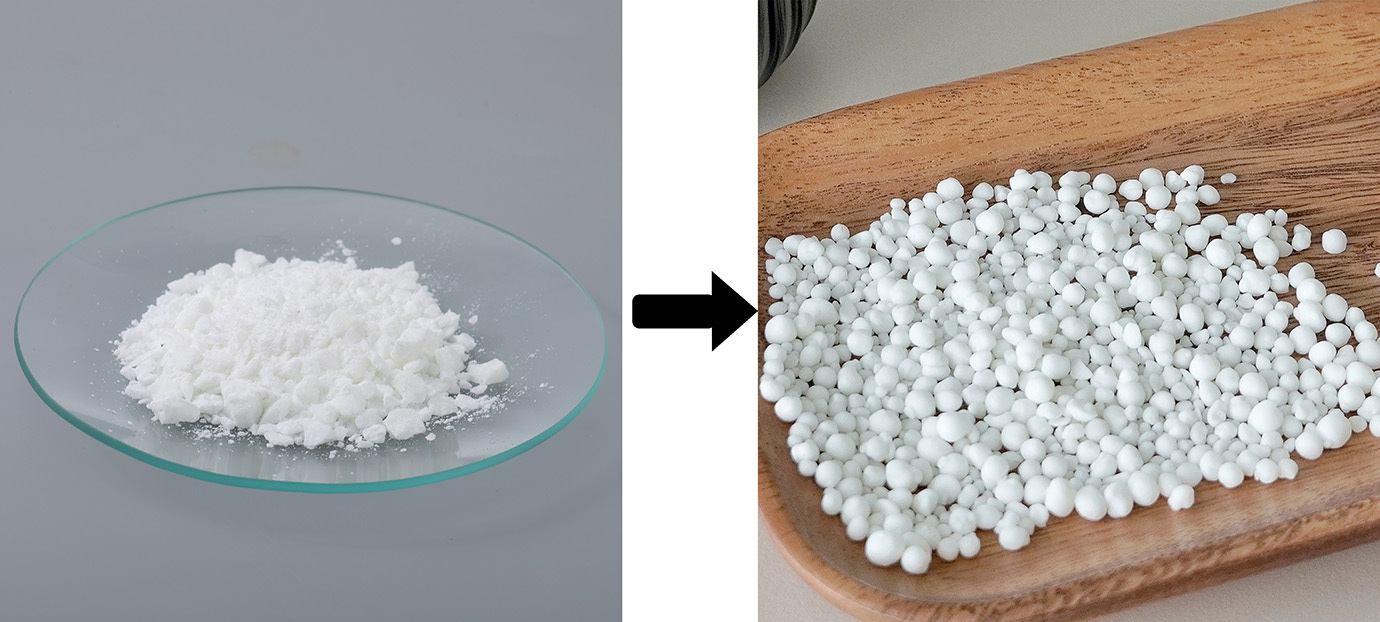

On the basis of the maleic acid ozone oxidation method, Guolin New Materials has been continuously innovated and improved for more than ten years. Maleic anhydride is used as raw material and ozone oxidation is introduced to obtain glyoxylic acid. After distillation, 75% potassium formate solution or potassium formate is obtained. The production process is more mature and safe than the original maleic acid ozone oxidation process, with simple operation and few process steps. Now, Guolin New Materials glyoxylic acid products have obtained the safety information certification of cosmetic raw materials. In addition, the granulation crystallization process of Guolin New Materials has been continuously debugged and upgraded, and now it can produce crystal glyoxylic acid in the shape of small pearl grains with a diameter of 2-4mm.

The Guolin New Material High Purity Crystal Glyoxylic Acid Project fills the gap in the large-scale production of crystal glyoxylic acid in my country, which can not only meet the needs of domestic medicine, food and other industries for high-purity glyoxylic acid products, but also drive my country's glyoxylic acid product industry and its The healthy and rapid development of the subsequent derivative industry and the application of ozone generating equipment in the chemical industry are of great significance to promoting the development of the glyoxylic acid industry and the ozone generating equipment industry.